Miniature Diaphragm Pumps for air and vacuum

Customization

Customization is our standard practice: all our pumps can be modified to meet your specific requirements. And within a few days. Customized range of micro pumps:

-

Voltage: DC 3V/6V/9V/12V/24V

-

Air flow: 0.5-22 L/min

-

Pressure: 0.5-3.5 bar (7.2-138psi)

-

Vacuum: -30-85 kpa (225-637mmHg))

-

Diaphragm Material: EPDM/FKM

• Efficient and durable design

• Smallest size and lightest weight

• Oil-free and non-contaminating media

• Maintenance free and easy to install

• Excellent air tightness

• Long life, continuous operation

• Low noise and low vibration

• Analytical & Diagnotics

• Gas Analysis & Monitoring

• Precision Dosing

• Medical Monitoring

• Inkjet Printing

• Industrial Vacuum and Pressure Generation

• Massage Devices

• Aeration Systems

What Can You Get? When You Buy A Sample.

- Sample inspection video

- ROHS or CE certificate

- Specification

- Transport follow-up

- After-sales follow up

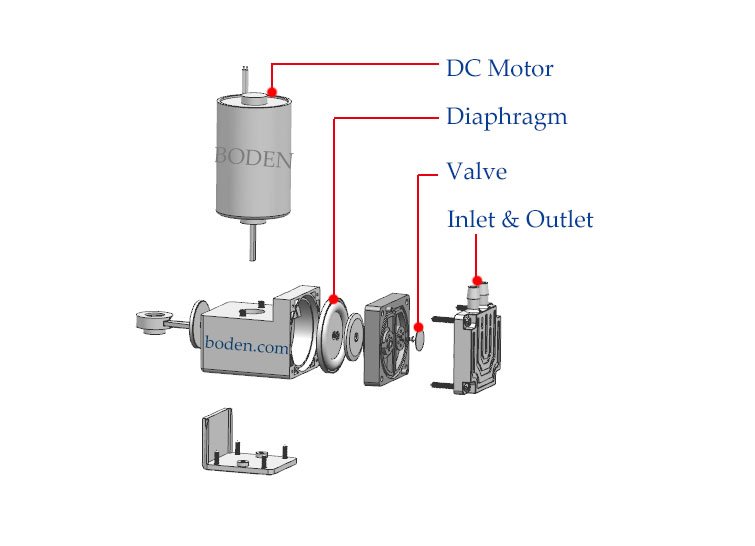

Miniature Diaphragm Pumps Structure

Construction Principle:

A miniature diaphragm pump typically consists of several main components, including a diaphragm, a motor, a valve, and a housing. The diaphragm is a flexible membrane that is used to move gas or vacuum. The motor provides the power to move the diaphragm, and the valve controls the flow of gas or vacuum through the pump. The housing encloses and protects the other components of the pump.

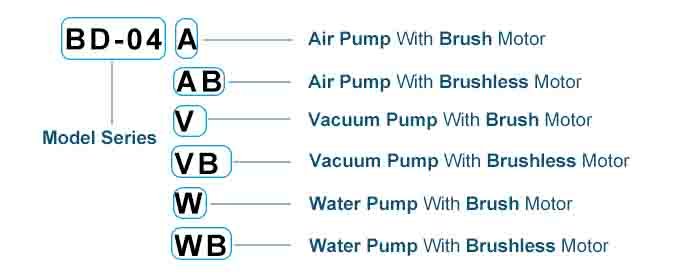

- “BD”—BODENFLO

- “01”—Pump series

- “A”—Air pump (Inflatable)

- “V”—Vacuum pump (Suction)

- “B”—Brushless motor

- The flow rate is no pressure flow rate.

- Conventional brush life is 1000 hours, brushless life is 3-5 times longer.

- Diaphragm and valve material, conventionally EPDM.

- Parameters can be customised.

- Sample shipments by air

- Bulk shipments by sea

The cost of a miniature pump with brush motoe is 5-20 USD

The cost of a miniature pump with brusheless motor is 15-35USD

Diaphragm Air Vacuum Pumps products

BD-01A/BD-01V

Brush

Flow: 0.5-1 L/min

Pressure: 0.5-1 bar

Vacuum: 30-60kpa

45×15.5×25.5mm

Smallest size

BD-02A/BD-02V

Brush

Flow: 1-3.5 L/min

Pressure: 0.5-1.5bar

Vacuum: 30-65kpa

55x24x40mm

Low noise

BD-02AB/BD-02VB

Brushless

Flow: 1-3L/min

Pressure: 0.5-1 .5bar

Vacuum: 30-65kpa

53x24x40 mm

High stability

BD-03A/BD-03V

Brush

Flow: 3-7 L/min

Pressure: 2-3 bar

Vacuum: 45-70kpa

76x30x49 mm

Compact structure

BD-03AB/BD-03VB

Brushless

Flow: 3-6 L/min

Pressure: 2-3 bar

Vacuum: 45-65kpa

64x30x49 mm

Long life

BD-04A/BD-04A

Bursh

Flow: 7-22 L/min

Pressure: 2.5-3.5 bar

Vacuum: 75-82kpa

101x40x72 mm

Widely used

BD-04AB/BD-04VB

Bruhsless

Flow: 7-20 L/min

Pressure: 2-3.5 bar

Vacuum: 70-82kpa

92x40x72 mm

High quality

Micro Diaphragm Air Vacuum Pumps FAQ

The diaphragm of a miniature diaphragm pump is typically made of a flexible material such as rubber or silicone. The diaphragm is connected to the motor, which drives the movement of the diaphragm. As the diaphragm moves, it creates a vacuum or pressure that is used to pump gas or vacuum.

The valve of a miniature diaphragm pump is typically located between the diaphragm and the housing. The valve controls the flow of gas or vacuum through the pump, allowing it to be turned on or off and to be directed to different locations.

The housing of a miniature diaphragm pump encloses and protects the other components of the pump.

The housing is typically made of a durable material such as metal or plastic, and is designed to withstand the pressure and flow of the pump.

Overall, the structure of a miniature diaphragm pump consists of a diaphragm, motor, valve, and housing, which work together to move gas or vacuum.

There are several advantages to using miniature diaphragm pumps for gas and vacuum applications. Some of the key advantages include:

- Versatility: Miniature diaphragm pumps are highly versatile and can be used to pump gases, liquids, or vacuum. This makes them suitable for a wide range of applications, from medical devices to environmental monitoring.

- Small size and lightweight: Miniature diaphragm pumps are small and lightweight, making them ideal for applications where space is limited or where a small and portable pump is required.

- High pressures and flow rates: Miniature diaphragm pumps are capable of generating high pressures and flow rates, making them suitable for applications that require high performance.

- Durability and corrosion resistance: Miniature diaphragm pumps are typically resistant to corrosion and can operate in a wide range of temperatures and environments, making them highly durable and reliable.

- Ease of use: Miniature diaphragm pumps are typically easy to operate and maintain, making them a convenient and user-friendly option for many applications.

Overall, miniature diaphragm pumps offer a range of advantages, including versatility, small size and weight, high performance, durability, and ease of use. These factors make them a valuable tool for many gas and vacuum applications.

When purchasing miniature diaphragm pumps for gas and vacuum applications, there are several factors to consider in order to ensure that you choose the right pump for your needs. Some of the key factors to consider include the following:

- Flow rate and pressure requirements: Consider the flow rate and pressure requirements of your application and choose a miniature diaphragm pump that is capable of meeting these requirements.

- Compatibility with gases, liquids, or vacuum: If you will be using the pump for gas or liquid applications, make sure that the pump is compatible with the specific gases or liquids that you will be using. Similarly, if you will be using the pump for vacuum applications, make sure that the pump is capable of generating the required level of vacuum.

- Size and weight: Consider the size and weight requirements of your application and choose a miniature diaphragm pump that is small and lightweight enough to meet these requirements.

- Operating conditions: Consider the operating conditions of your application, such as temperature, humidity, and exposure to chemicals or other corrosive substances. Choose a miniature diaphragm pump that is designed to withstand these conditions.

- Price and quality: Consider the price and quality of the miniature diaphragm pump when making your purchase. Look for a pump that offers good value for money and is of high quality and durability.

By considering these factors, you can choose the right miniature diaphragm pump for your gas and vacuum applications.

Miniature diaphragm pumps are commonly used in a wide range of applications that require the movement of gas or vacuum. Some of the most common applications of miniature diaphragm pumps for gas and vacuum include the following:

- Medical devices: Miniature diaphragm pumps are commonly used in medical devices, such as portable oxygen concentrators, nebulizers, and inhalers. These pumps are used to move air and gases in order to provide oxygen to patients or to deliver medication.

- Analytical instruments: Miniature diaphragm pumps are often used in analytical instruments, such as gas chromatographs and mass spectrometers. These pumps are used to move gases and vacuum in order to separate and analyze chemical compounds.

- Environmental monitoring: Miniature diaphragm pumps are frequently used in environmental monitoring devices, such as air quality monitors and gas detectors. These pumps are used to move air and gases in order to measure the levels of various pollutants and gases in the environment.

- Laboratory equipment: Miniature diaphragm pumps are commonly used in laboratory equipment, such as vacuum pumps and vacuum ovens. These pumps are used to create vacuum or pressure in order to perform various laboratory procedures and experiments.

- Industrial processes: Miniature diaphragm pumps are often used in industrial processes, such as vacuum packaging and vacuum filtration. These pumps are used to move vacuum or gases in order to perform specific industrial tasks.

Overall, miniature diaphragm pumps are widely used in a range of applications that require the movement of gas or vacuum. These pumps are particularly useful for applications that require a small and lightweight pump with high performance and durability.

Yes, we are a manufacturer of miniature pumps. We specialize in the production of miniature diaphragm pumps for gas and vacuum applications. Our manufacturing facility has a capacity of 200,000 units per year, and we are ISO9001 certified. We have been in the miniature pump manufacturing business for [15] years, and we are known for our high-quality products and excellent customer service.

Manufacturing is the process of creating products by assembling raw materials and components into finished goods. This process is essential for businesses that produce their own products, as it allows them to control the quality and consistency of their products, and to customize them to meet the needs of their customers.

There are several key benefits of manufacturing for businesses. Some of the most important benefits include:

- Greater control over product quality: By manufacturing their own products, businesses have more control over the quality of the products they produce. This can help to ensure that their products are of consistently high quality and meet the expectations of their customers.

- Increased customization and flexibility: Manufacturing allows businesses to customize their products to meet the specific needs of their customers. This can be particularly important for businesses that produce products for niche markets or that need to produce products to order.

- Reduced reliance on third-party suppliers: By manufacturing their own products, businesses can reduce their reliance on third-party suppliers and have more control over their supply chain. This can help to reduce supply chain disruptions and ensure that businesses have access to the materials and components they need to produce their products.

- Greater potential for innovation: Manufacturing can also provide opportunities for businesses to innovate and develop new products or processes. This can help businesses to stay ahead of their competitors and to differentiate themselves in the marketplace.

Enough About Us. Let's Talk About Your Miniature Diaphragm Pump Project Now.

Developing a new unique micro air pump is easy here in BODENFLO

- Professional feedback within 8 hour

- Full capabilities to reply on

- Best possible prices for you

- Fast sample in 1- 3 days

- Fast delivery in 1- 3 days